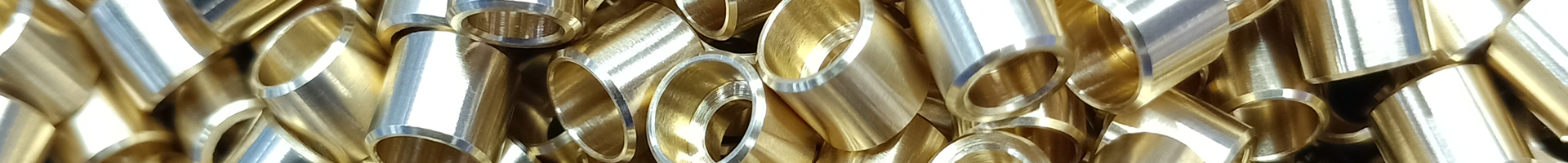

Brass Machined Parts

Brass has the characteristics of high wear resistance, high strength, high hardness, strong chemical resistance and easy processing. So it is very popular. Shinway has been manufacturing precision machined brass parts such as valves, water pipes, air conditioners and radiators components.

Advantages Of Brass Machined Parts

Brass machined parts have several key advantages over machining other materials. Brass turned parts and components are durable, cost effective and even provide a tighter seal for fittings. In addition, brass machining parts are highly resistant to heat and corrosion! What's more, Shineway's brass parts are easy to machine with high precision, which can meet your specifications and standards!