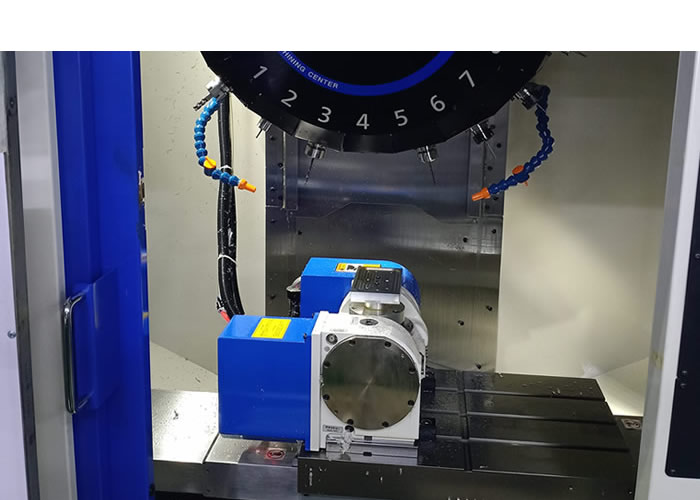

Precision CNC Machining

Shineway precision machining services are highly sought after in multiple industries because we require our CNC machinists to truly understand their machine’s behaviors – not just the electronic make up, technical controls, and power button. We perform a number of ultra precision machining services, such as 3 and 4 Axis Milling, 5 Axis Machining, Swiss turn/lathes, gear machining.

3 Axis

Evolved from the practice of rotary filling, 3 axis machining is an average manual milling technique cutting parts on three axes, the X, Y, and Z axes. While many machines have a moving bed, the 3 axis milling centers stand still while the cutter itself operates instead.

3-axis milling is capable of creating the same products as 4 axis and 5 axis machines, but the 3 axis machines cannot deliver the same level of detail or efficiency as its predecessors. 3 axis can cut individual features during operations, but it cannot match the work of a 5 axis in quality or profitability.