By any modern statistical measure, Shineway Manufacturing meets or exceeds the quality standards of the world's most demanding industries.

At

Shineway Hardware, we’re dedicated to making the world’s finest parts and products for our customers. We’re a one-stop shop for mechanical engineering, product design, volume production service. We continue to excel in the CNC machining of very tight tolerance, ultra high precision components.

Send us your 3D CAD model, we will provide you with a free quote immediately.

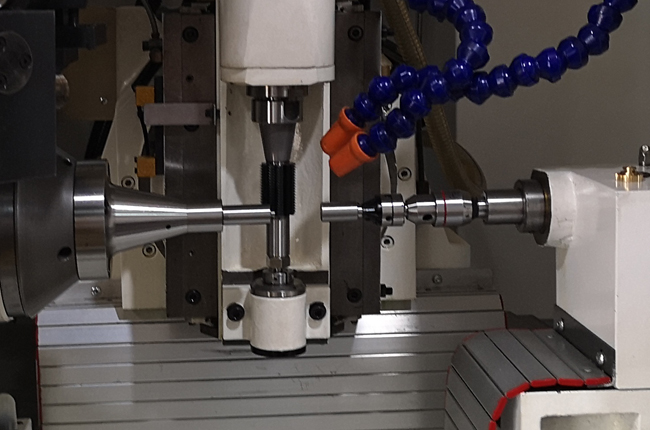

With our state-of-art equipment, Shineway Hardware precision machining services are highly sought after in multiple industries. We perform a number of ultra precision machining services, such as 3 and 4 Axis Milling, 5 Axis Machining, Swiss turn/lathes, gear machining.

Equipped with our advance multi-axis machines, Shineway Hardware is able to provide precision micromachining service for mircro machined components such as medical components, optical components, semiconductor components and much more.

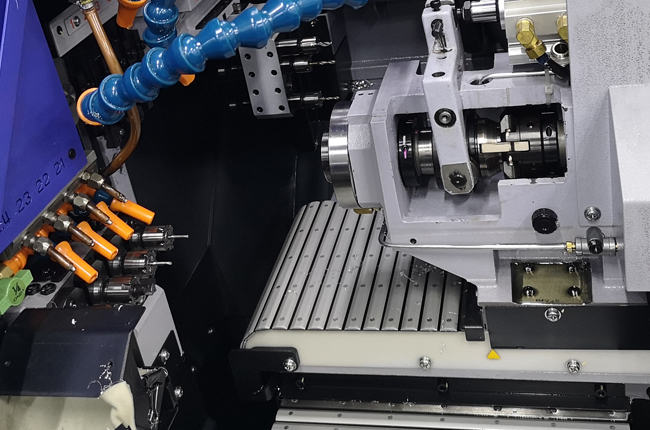

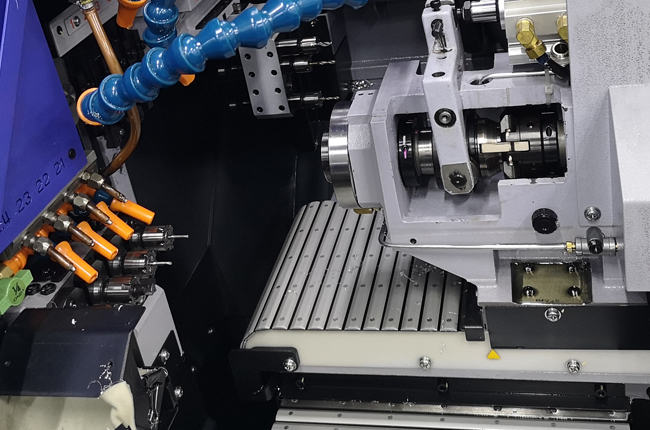

Shineway Hardware uses the latest technology with CNC Swiss machining lathes with 5-axis machining capabilities, excellent accessibility, and modular tooling system. Your Swiss machined precision parts can be manufactured with ease and perfection.

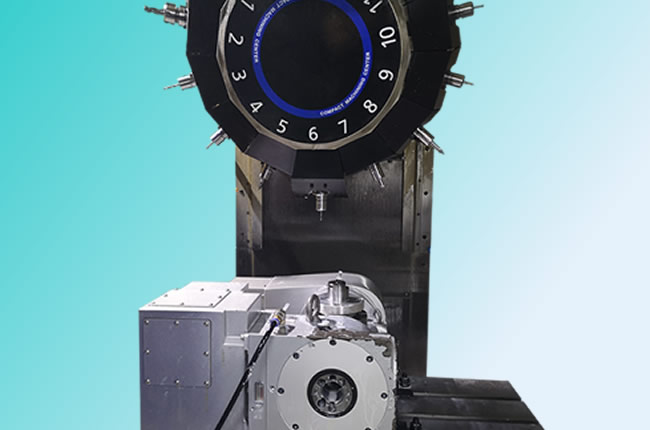

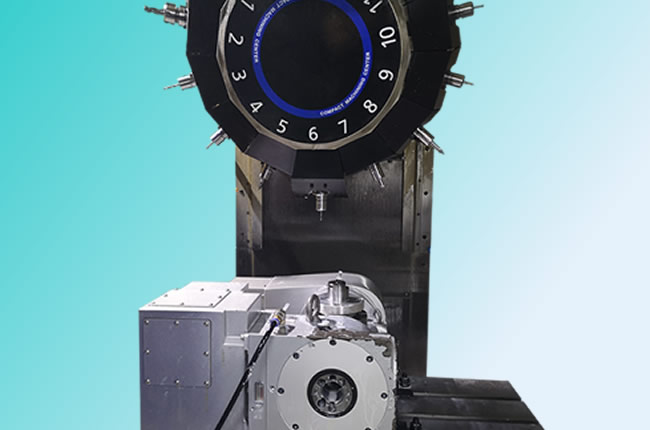

CNC milling is used to apply a machined surface finish on plastic or metal, or for creating complex 3D shapes. We use domestic and imported Brother 3, 4 and 5-axis CNC milling centers with quick-change tooling, programmed using advanced software.

Our CNC lathes enable high speed and quality turning of both plastics and metals. The turning process allows for complex external geometries and internal bores to be generated. Our turning capacity is available for prototypes through to high-volume production.

Shineway specializes in the development and design of precision small and medium modulus gears, racks, worm gears, gear wheels, spur gears, bevel gears and precision machinery parts. We have excellent production equipment and professional testing.