Making products with consistent high-quality requires good process control

techniques combined with advanced equipment. At Shineway, we have advanced inspection measuring and

testing equipment in-house to qualify all incoming raw materials, while our modern metrology lab ensures

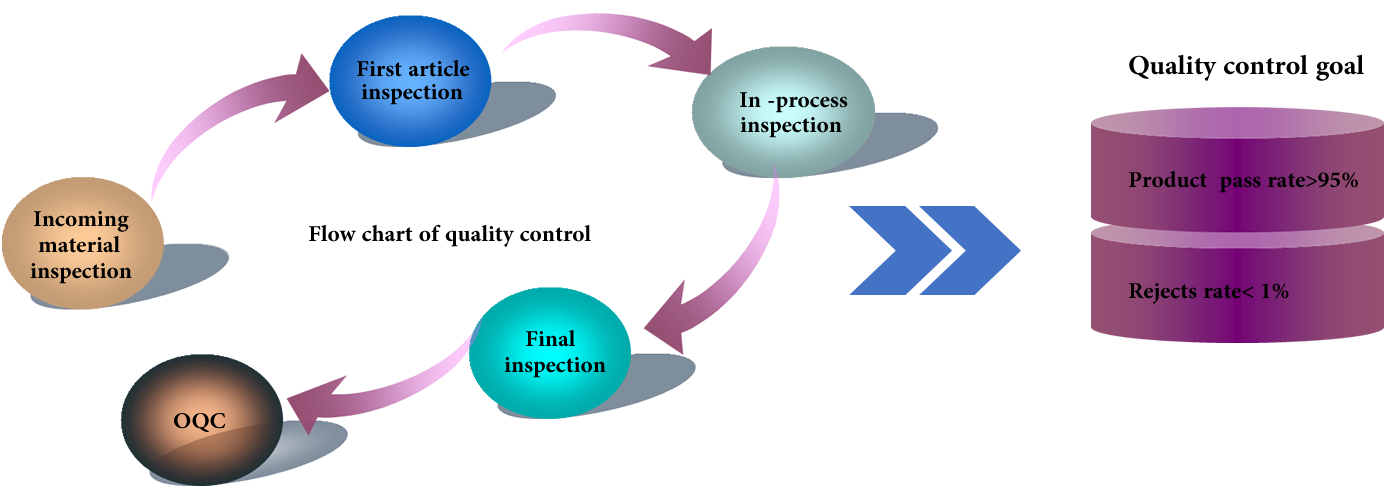

that your parts meet your exact specifications. Further, we make sure every project follows these steps

for quality assurance:

- Design for manufacturing review for all quotes provided

- Contract review upon receipt of PO

- Incoming materials inspection

- First article and in-process inspection

- Final inspection and testing with reports and certifications as required

ISO Certified

We are proud to be fully certified and compliant with ISO 9001:2015. This

demonstrates our commitment to continuous quality improvement, respect for our workers and for the

environment.